CAM Used Equipment

Used Full Weighing and Pre-made Bagging System

(14MHW+CR8-250Z)

This full weighing and pre-made bagging system is in excellent condition and has been sparingly used. This packaging solution is extremally versatile and can weigh and bag a wide variety of products such as confectionary, snack foods, frozen foods, dry fruits, pet foods, and more!

The multihead weigher ensures accurate measuring of a pre-determined weight, before being released into the CR8-250Z system where the products are precisely filled and sealed into each pre-made bag up to 35 packages per minute.

Full System Includes:

- 70 Degree Incline Conveyor

- Large Vibration Hopper

- 14 Multihead Weighing System (Dimple Plated) 1.6L

- Full Support Platform with stairs and railings

- Complete Divert System

- CR8-250Z Pre-made Bagger (Up to 35 ppm)

70-Degree Incline Conveyor Key Features:

- Belt is made of food grade PP

- Vibration Feeder will feed materials to carrying belt according to signal requirement

- Power supply: 220V Single Phase 60HZ

- Vibrator Hopper Size: 650L*650W; 25.5“L x 25.5“W

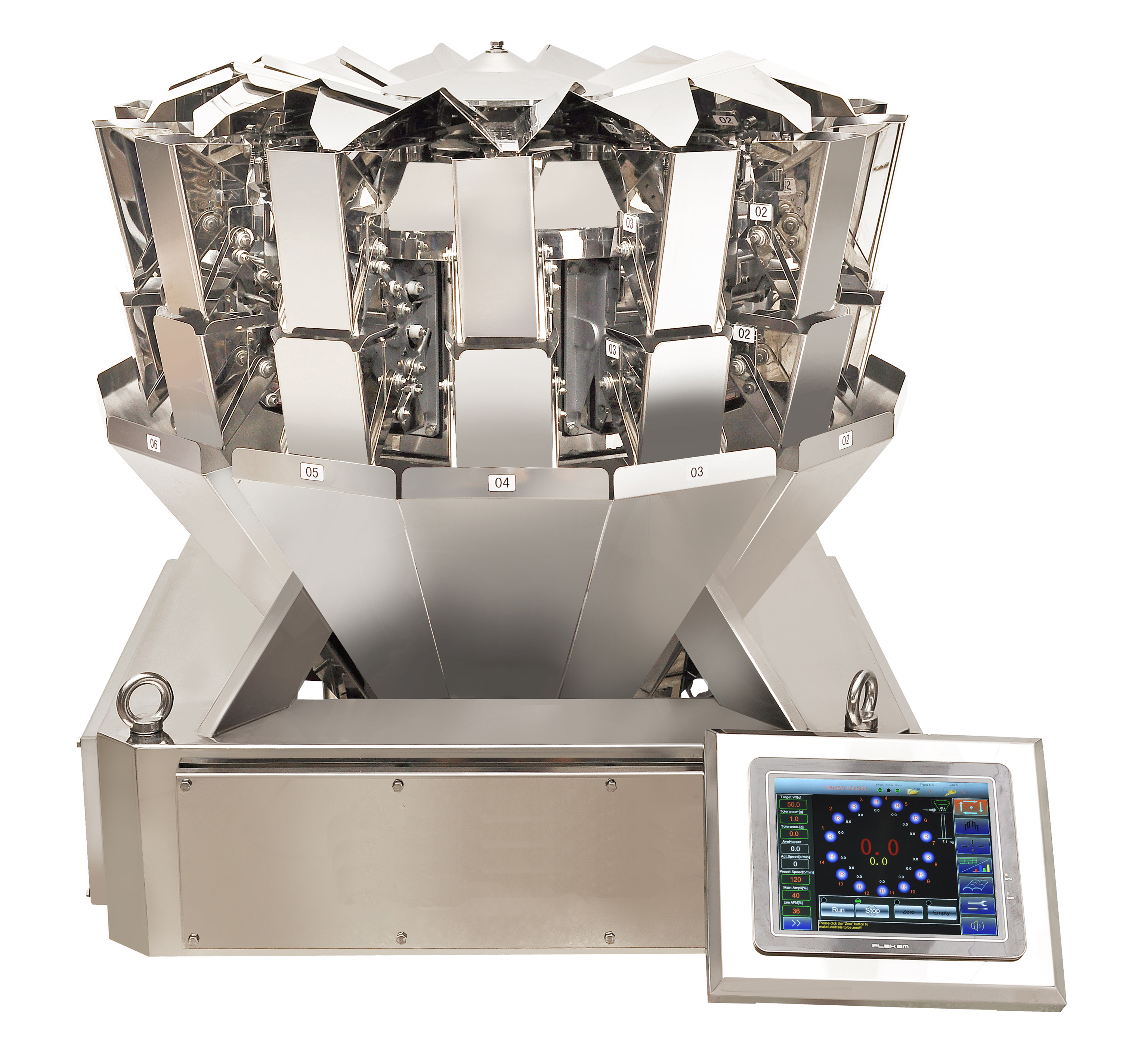

14 Multihead Weigher Key Features:

- Stainless steel construction

- Production records can be checked at anytime or download to PC

- Pre-set stagger dump function to stop blockages

- Food contact parts are easily disassembled without tooling for easy cleaning and maintenance

- Weighing Range: 10-2000 grams

- Accuracy: + 0.2-2.0 grams

- Weigh Bucket Size: 1.6L

- Control Panel: 9.7″ Touch Screen

- Power Supply: 220V / 60Hz / 12A /1500W

Stainless Steel Support Platform Key Features:

- Platform is compact, stable, and safe with guardrail and ladder

- Made of #304 stainless steel

- ***Dimension (mm): 2150(L) x 2300(W) x 2100(H); 7.05ft x 7.6ft x 6.8ft

CR8-250Z Pre-made Bagger Key Features:

- Easily operated, PLC controlled, and properly integrated with built-in touch screen and electric control system. The HMI is user-friendly.

- All product contact parts are stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food.

- With different feeders, the same bagging system can be changed to pack solids, liquids, thick liquids, powder, and many other items.

- The width of the bags can be adjusted by an electrical motor. (W:100-250 mm L:100-350 mm)

- Bagging Speed: Up to 35ppm

- Voltage: 220V / 3 phase / 60HZ