CAM Used Equipment

Used Full Weighing and Pre-made Bagging System

(Auger Filler + 14MHW+CR8-250Z)

This full weighing and pre-made bagging system is in excellent condition and has been sparingly used. This packaging solution is extremally versatile and can weigh and bag a wide variety of products such as confectionary, snack foods, frozen foods, dry fruits, pet foods, and more!

The multihead weigher ensures accurate measuring of a pre-determined weight, before being released into the CR8-250Z system where the products are precisely filled and sealed into each pre-made bag up to 35 packages per minute.

Full System Includes:

- 70 Degree Incline Conveyor

- Large Vibration Hopper

- 14 Multihead Weighing System (1.6L)

- Full Support Platform with stairs and railings

- Complete Divert System

- CR8-250Z Pre-made Bagger

- Auger Filler

- Printer Brackets

- 2 x Desiccant Feeders with Protective Cover

- 2 x Desiccant Feeder Support Stand

- Track System for hand Guided Bagger Moving

- Curved Conveyor

- Exit Conveyor

- Checkweigher

- Nitrogen Generator

70-Degree Incline Conveyor Key Features:

- Belt is made of food grade PP

- Vibration Feeder will feed materials to carrying belt according to signal requirement

- Power supply: 220V Single Phase 60HZ

- Vibrator Hopper Size: 650L*650W; 25.5“L x 25.5“W

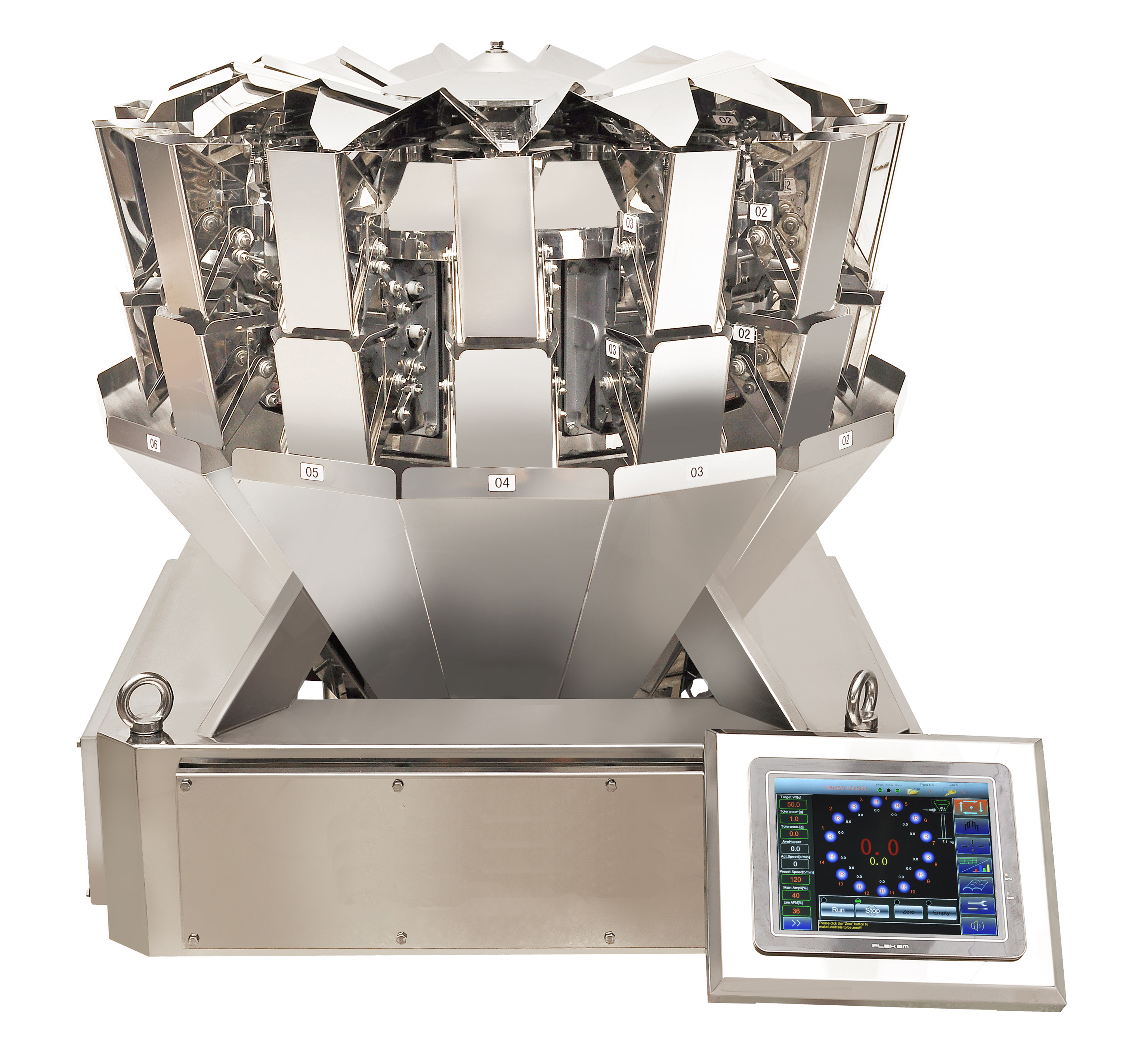

14 Multihead Weigher Key Features:

- Stainless steel construction

- Production records can be checked at anytime or download to PC

- Pre-set stagger dump function to stop blockages

- Food contact parts are easily disassembled without tooling for easy cleaning and maintenance

- Weighing Range: 10-2000 grams

- Accuracy: + 0.2-2.0 grams

- Weigh Bucket Size: 1.6L

- Control Panel: 9.7″ Touch Screen

- Power Supply: 220V / 60Hz / 12A /1500W

Stainless Steel Support Platform Key Features:

- Platform is compact, stable, and safe with guardrail and ladder

- Made of #304 stainless steel

- ***Dimension (mm): 2150(L) x 2300(W) x 2100(H); 7.05ft x 7.6ft x 6.8ft

CR8-250Z Pre-made Bagger Key Features:

- Easily operated, PLC controlled, and properly integrated with built-in touch screen and electric control system. The HMI is user-friendly.

- All product contact parts are stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food.

- With different feeders, the same bagging system can be changed to pack solids, liquids, thick liquids, powder, and many other items.

- The width of the bags can be adjusted by an electrical motor. (W:100-250 mm L:100-350 mm)

- Bagging Speed: Up to 35ppm

- Voltage: 220V / 3 phase / 60HZ

Desiccant Feeder

- Automatic pouch feeding, cutting and dispensing, for use with a variety of materials such as bottles, bags, cartons or pouches.

- Servo motor and PLC control system, advanced digital operation making it both easy and convenient. Offers different sizes of pouch.

- Features an alarm control function that activates with no package, fault self-test, desiccant bags not entering the package, etc. Ensures the continuity and accuracy.

- Optical, mechanical and electronic integration, intelligent sensor technology

Checkweigher

- It is suitable to check weight of various product, over or less weight will be rejected out, qualify bags will be passed to next equipment.

- Touch screen and PLC, more stability and easier to operate.

- Blow off rejection device.

Nitrogen Generator

- Produce nitrogen gas, which is then injected into the packaging to replace the oxygen and helps extend the shelf life of perishable products by reducing the oxygen content, which slows down the oxidation and deterioration of the product.

- Voltage: 220V single phase 60HZ

- Nitrogen Capacity: 5Nm3/h

- Power: 5W

- Nitrogen Purity: ≥99.5%

- Purity level calculated by a measuring instrument on the Nitrogen Generator