Author: Ryan Cusack

The Importance of Customization:

Tailoring Packaging Equipment to Your Needs

When it comes to packaging your products, one-size-fits-all solutions are often not the answer. Every business is unique, with its own set of requirements and challenges. Just like your products and business being unique, your packaging equipment should also be tailored to meet your specific processes. Investing in packaging equipment that is tailored to your specific needs can lead to increased efficiency, cost savings, and overall business success. In this blog post, we will explore the significance of customization in packaging equipment and how it can benefit your company.

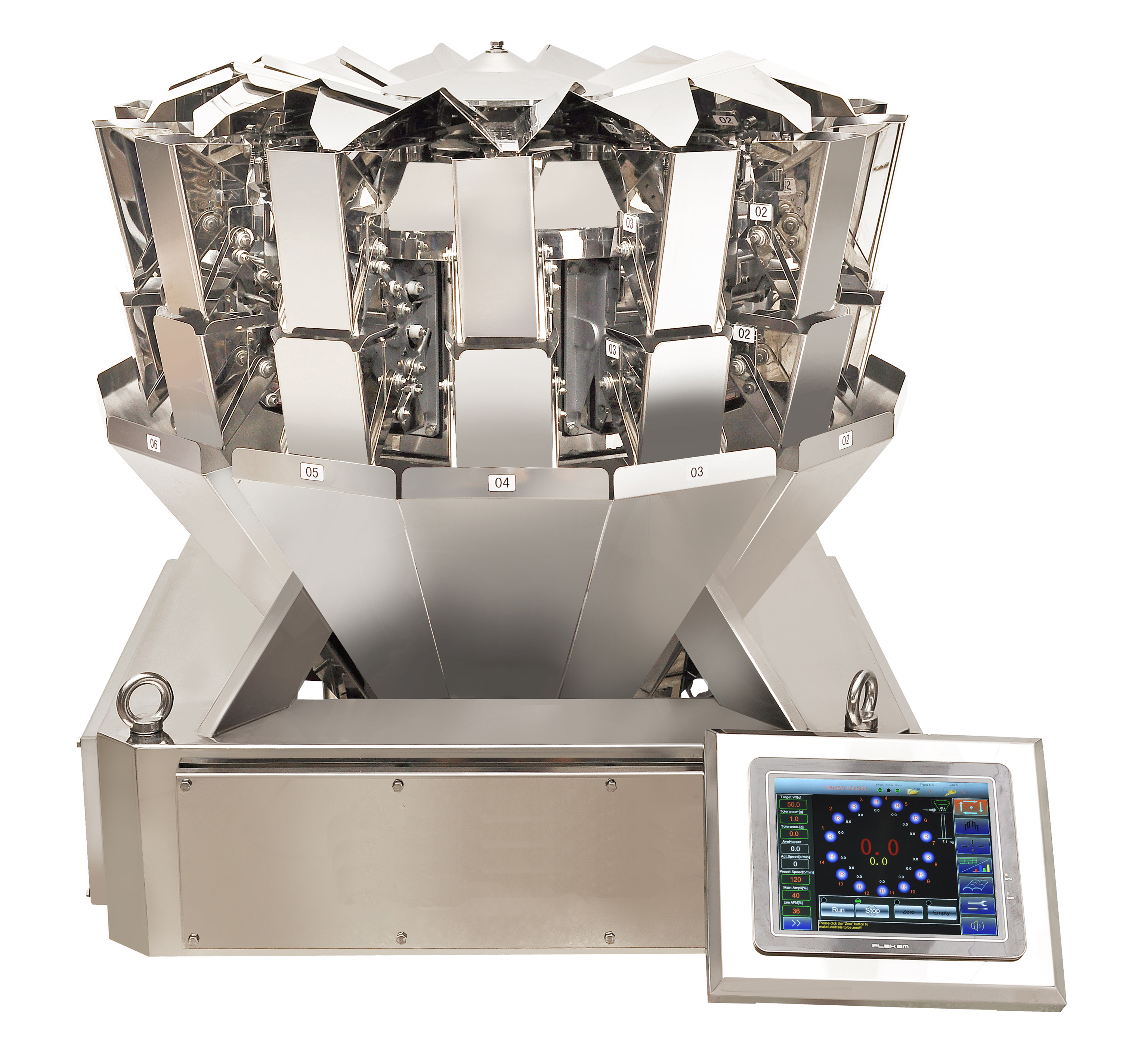

- Enhanced Efficiency and Performance: Efficiency is the lifeblood of any successful packaging operation. Customized packaging equipment is designed to work seamlessly with your products and processes by aligning the equipment with your specific needs, which will optimize processes, minimize waste, and increase productivity. For instance, if your products come in various shapes and sizes, having adjustable conveyors, weighers that can run all of your products, and customizable settings can streamline the packaging process, leading to faster throughput and cost savings. Customization eliminates the need for time-consuming adjustments and workarounds that are often necessary with generic equipment.

2. Improved Product Protection: The right packaging equipment customized to your needs ensures superior product protection. By understanding your unique requirements, such as fragility or sensitivity to certain environmental factors, your packaging equipment should be tailored to your needs whether that is specialized cushioning, tamper-evident features, or climate-controlled packaging. Customized packaging machinery can also include features like temperature control or moisture resistance, offering optimal product protection required for your specific items that generic packaging equipment may not.

3. Enhanced Branding and Consumer Experience: Packaging is not just about protecting products; it is often the first point of contact between your brand and the consumer and is a powerful branding tool. Customized equipment allows you to incorporate your brand elements seamlessly into the packaging process. From customized box sizes and shapes to the inclusion of branding elements like custom colors, graphics, logos or taglines, personalized packaging equipment enables you to create a unique and memorable consumer experience. When your packaging aligns with your brand image, it helps to strengthen brand recognition and loyalty.

4. Flexibility and Scalability: In today’s fast-paced business environment, the ability to adapt to changing market demands is crucial. Customized packaging equipment can be designed to be modular and flexible, making it easier to accommodate new products, packaging styles, or production processes. As your product line expands, having equipment that can easily accommodate new sizes, shapes, or packaging materials ensures a seamless transition. This adaptability ensures that your packaging operation remains agile and can respond quickly to market shifts without the need for a complete equipment overhaul.

5. Cost-effectiveness in the Long Run: While custom packaging equipment may seem like a larger upfront investment, it often leads to significant cost savings in the long run. Off-the-shelf equipment may require additional accessories or modifications to meet your specific requirements, and these add-ons can quickly become expensive. Customized solutions are built with your needs in mind, eliminating the need for costly modifications, unnecessary features, reducing maintenance expenses, and maximizing efficiency. Customized packaging equipment is designed to minimize waste, decrease downtime, and increase productivity, resulting in improved ROI over time.

In an era where personalization and differentiation are crucial for success, customizing your packaging equipment is no longer an option but a necessity. From improved efficiency and product protection to enhanced branding opportunities and long-term cost savings, customization offers many benefits for your business.

Investing in packaging equipment tailored to your unique needs, you’re not just investing in equipment; you’re investing in the success and sustainability of your business. Make the smart choice—choose customization and unlock the full potential of your packaging operation that sets you apart from the competition, explore CAM Packaging Systems Today!

As we’ve explored the significance of customization in packaging equipment, it’s evident that a one-size-fits-all approach is no longer sufficient. Every business has its own unique demands, products, and goals. By investing in customized packaging equipment, you’re investing in the future of your brand and the satisfaction of your customers.

Now, it’s your turn to take action. Are you ready to elevate your packaging game and stand out in the market? Reach out to our experts and discover how tailored packaging equipment can transform your business. Let’s embark on this journey together and redefine the way you package your success.

Contact us today and unlock the potential of personalized packaging solutions that perfectly suit your needs. Your brand deserves to shine, and we’re here to make it happen.

Sources:

PMMI, The Association for Packaging and Processing Technologies: Sustainability and Technology – the Future of Packaging and Processing. https://pmmi.docsend.com/view/bckpxme7bdchzw9g

Robotic Palletizing & EOL Solutions:

CAM Metal detector testing on pre-made candy bags (model: CMD-4020)

This machine automatically inspects individual bags to ensure no trace of metal contaminates are in the packages. Utilizes enhanced detecting ability by utilizing digital signal processing, and user friendly 7” touchscreen control with automatic product set up, product pre-programming with data collection, and multi-level password protection.

If using metalized packaging, we offer a throat metal detector that checks all products after they are weighed and before they are dropped into the packages.

Other Robotic Palletizing & EOL Solution Videos

CAM Collaborative robot palletizer running off sealer

Automatic pallet wrapping solution on in/outfeed conveyors

Checkweigher and X-ray inspect machines testing

Checkweigher testing weight accuracy with push arm reject

CAM Collaborative robot palletizer running at tradeshow

Robotic Palletizing & EOL Solutions:

CAM Checkweigher testing weight accuracy with push arm reject

This machine automatically verifies correct quantity in a package or to confirm accurate weights of product either prior or after primary packaging. High accuracy load cell and stability and stainless steel #304 structure ensures stable performance and precise weighing.

Other Robotic Palletizing & EOL Solution Videos

CAM Collaborative robot palletizer running off sealer

Automatic pallet wrapping solution on in/outfeed conveyors

Checkweigher and X-ray inspect machines testing

Metal detector testing on pre-made candy bags

CAM Collaborative robot palletizer running at tradeshow

Robotic Palletizing & EOL Solutions:

CAM Fully automatic pallet wrapping system on infeed and outfeed roller conveyor

This machine automatically wraps pallets as they enter the operating station before they are moved down the line and the next pallet automatically enters. One machine can run a variety of different sized pallets with no changeover between.

Streamline your operations with precision and speed as our advanced technology effortlessly wraps and secures pallets, ensuring stability and protection during transit.

Other Robotic Palletizing & EOL Solution Videos

CAM Collaborative robot palletizer running off sealer

Checkweigher and X-ray inspect machines testing

Metal detector testing on pre-made candy bags

Checkweigher testing weight accuracy with push arm reject

CAM Collaborative robot palletizer running at tradeshow

Robotic Palletizing & EOL Solutions:

CAM checkweigher and x-ray machines inspect finished products off full pre-made bagging line

The X-ray and check weighing machines are inspecting finished packages as they come of a full CR8-250Z pre-made bagging line to ensure the bags do not contain any foreign objects and that every bag meets the specific weight requirement of each project.

Automatic blow off reject systems are built in to ensure safety and weight requirements are met while alos maintaining the operational speed requirements. Also offer push arm reject systems for heavier products and packages.

Other Robotic Palletizing & EOL Solution Videos

CAM Collaborative robot palletizer running off sealer

Automatic pallet wrapping solution on in/outfeed conveyors

Metal detector testing on pre-made candy bags

Checkweigher testing weight accuracy with push arm reject

CAM Collaborative robot palletizer running at tradeshow

Robotic Palletizing & EOL Solutions:

CAM Collaborative robotic palletizer running cases of chocolate off a case sealer machine

This robot accurately picks and places cases up to 30KG (66lbs.), seamlessly constructs sturdy pallets and streamlines your logistics.

Advanced human collaborative technology that allows humas to safely work alongside the machine, power and force limiting technology and pinchless geometry protects worker from potentially harmful contact situations.

Sensor on base of palletizer creates three different operating speed modes depending on workers proximity to the machine in order to maximize safety and efficiency.

Other Robotic Palletizing & EOL Solution Videos

Automatic pallet wrapping solution on in/outfeed conveyors

Checkweigher and X-ray inspect machines testing

Metal detector testing on pre-made candy bags

Checkweigher testing weight accuracy with push arm reject

CAM Collaborative robot palletizer running at tradeshow

Robotic Palletizing & EOL Solutions:

CAM Collaborative robotic palletizer running cases of chocolate at tradeshow

This robot accurately picks and places cases up to 30KG (66lbs.), seamlessly constructs sturdy pallets and streamlines your logistics.

Advanced human collaborative technology that allows humas to safely work alongside the machine, power and force limiting technology and pinchless geometry protects worker from potentially harmful contact situations.

Sensor on base of palletizer creates three different operating speed modes depending on workers proximity to the machine in order to maximize safety and efficiency.

Other Robotic Palletizing & EOL Solution Videos

CAM Collaborative robot palletizer running off sealer

Automatic pallet wrapping solution on in/outfeed conveyors

Checkweigher and X-ray inspect machines testing

Metal detector testing on pre-made candy bags

Checkweigher testing weight accuracy with push arm reject

Case Erecting & Sealing Solutions:

CAM Fully automatic case erecting, sealing, and filling solution for bags of chocolate

This system automatically counts 5 bags per carton before erecting the case, filling with product, and sealing the packed case at a high speed and accuracy.

This system can fill larger cases with multiple rows of products and even integrate directly from the bag filling process to make the system fully automatic, shown in this video filling bags and packing an 18 count into a case.

Other Case Erecting & Sealing Solution Videos

CAM Automatic case erecting and sealing full line

Automatic weighing of chocolate bites and carton filling

Top and bottom sealer running cases of various sizes at once

Case erecting and sealing system running magazines into cases

Automatic case packing hinges by count and sealing

Case Erecting & Sealing Solutions:

CAM Automatic case packing hinges by count and sealing top and bottom with tape

This solution automatically measures the hinge products by target count and drops into erected cases before being securely sealed with tape.

All our case sealing systems can be integrated into a palletizing line to be automatically place on pallets for efficient packing operations. Can run a wide variety of products on our case filling applications and can meet your specific speed requirements by utilizing our different case erecting and sealing machines.

Other Case Erecting & Sealing Solution Videos

CAM Automatic case erecting and sealing full line

Automatic weighing of chocolate bites and carton filling

Top and bottom sealer running cases of various sizes at once

Case erecting and sealing system running magazines into cases

Automatic case packing hinges by count and sealing

Case Erecting & Sealing Solutions:

CAM Top and bottom sealer running various sizes of cases at once

This case sealer has an ability to run a variety of case sizes on one machine with no adjustment or changeover. An operator enters the case into the sealing area where the sensor detect the box and the top and side guides close around it.

Once both guides are pressed against the carton, the side belts start and run the carton through the taping section, where top and bottom tape heads apply the pressure sensitive tape to securely seal the case for shipping or storage.

Other Case Erecting & Sealing Solution Videos

CAM Automatic case erecting and sealing full line

Automatic weighing of chocolate bites and carton filling

Case erecting and sealing system running magazines into cases

Fully automatic erecting, filling, and sealing bags of chocolate into cases

Automatic case packing hinges by count and sealing